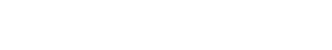

THE MONSTER

The latest model in our Horizontal Series Cookers at Stump’s Smokers. This is the perfect choice for the BBQ Professional who needs the capacity for larger cooks and desires the versatility of being able to use charcoal or wood. This single factor allows the cook to be able to feature different flavor profiles in his arsenal of cooking for competition or customers alike.

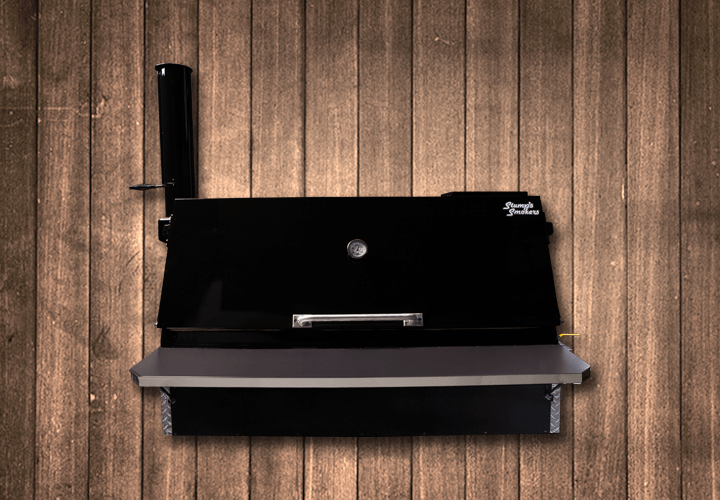

Whether it’s loading wood down the chute or using the Flavor Generator Box, there is more to this cooker than meets the eye.

BASE PRICE $10,200.00

THE MONSTER SPECIFICATIONS

| Overall Dimensions | 85″H x 78″W x 46″D |

| Internal Cooking Space | 21″H x 46″W x 28″D |

| Overall Weight | 800 lbs. |

| Cook Temp Range | 175 – 550 degrees |

| Charcoal Qty | 25 lbs. |

| Bottom Rack Size | 45″W x 28″D |

| Top Rack Size | 45″W x 22″D |

| Rack Spacing | 6″ apart |

| Color | Black |

| Standard Features | 12” Floor Stand Aluminum door handles Hydraulic door assist Guru Ball valve adapter Chrome Stump’s BBQ Thermometer in door |

OPTIONAL ACCESSORIES

| 12″ Floor Stand | $350.00 |

| 18″ Legs | $225.00 |

| Replacement Rack | $260.00 |

| Replacement Hydraulic Strut | $45.00 |

| Replacement Gasket per/ft | $5.68 |

| Replacement Thermometer | $35.00 |

CAPACITY

| Baby Back Ribs | 45 |

| St. Louis Style Ribs | 50 |

| Large Brisket | 20 |

| Boston Butt | 20 |

| Chicken Halves | 40 |

ORDER THIS COOKER

FREQUENTLY ASKED QUESTIONS

So by controlling the amount of oxygen that is fed in, we can control the amount of “fire” or the temp in the cook chamber. That’s where electronics like a BBQ Guru come in handy — it uses a fan to force oxygen into the ball valve when needed. Forcing the oxygen in will allow the temp to rise faster (helping to recover the heat in the cook chamber after the door has been opened). But you can always let it recover naturally, just takes a little longer.

The heat/smoke moves through the cook chamber of a gravity feed much slower than in a typical offset stick burner smoker. Therefore the cook chamber doesn’t dry out as much either — this creates a nice moist cooking environment that doesn’t tend to cause meat to dry out as fast while it is cooking.

Once inside the cook chamber, the divider plate evenly distributes the air and heat and allows the natural convection process to begin. Once this process has started air and heat movement naturally drafts up, around and out through the exhaust stack. So by controlling the amount of oxygen that is fed in, we can control the amount of “fire” or the temp in the cook chamber. The heat/smoke moves through the cook chamber of a gravity feed much slower than in a typical offset stick burner smoker. Therefore the cook chamber doesn’t dry out as much either — this creates a nice moist cooking environment that doesn’t tend to cause meat to dry out as fast while it is cooking.

The Diamond Match Co. makes a product called Strike-a-Fire that can be used. Remove one of the big matches from the package and light on the side of the box allowing the flame on the end to become the size of a large lemon, open the charcoal chute door and drop into (a clean charcoal chute) and land on the fire grate. Check to see that there still active fire on the match. Drop about 1 pound of charcoal on top of the light match and close the charcoal chute door and you should get ignition. Open the ball valve to the handle position of 7 o’clock and close the fire box door, the rain cap to about a 1/3 of the gap. After a notable fire is started, latch the fire box door, open the ball valve to the handle position of 7 o’clock and let come up to desired temp with the adjustment of the ball valve.

The second method, drop about ½ of a chute of charcoal on top of the fire grate and close the charcoal chute door. Using a lit Plumber’s Torch, stick the nozzle through the fire grates and allow the torch to light several pieces of charcoal. Once the charcoal is lit, close the fire box door until the is a 1 inch crack from closing, the rain cap should also be at about a 1/3 of the gap. After a notable fire is started, latch the fire box door, open the ball valve to the handle position of 7 o’clock and let come up to desired temp with the adjustment of the ball valve.

After allowing the smoker to cook at the set temp for one hour, open the door and (using a spray bottle filled with vegetable oil) spray the inside with oil coating all surfaces on the inside EXCEPT the gasket. Close the door and allow the smoker to cook for 3 hours at the set temperature. At the end of 3 hours, close the ball valve and allow the Smoker to begin shutting down. Allow the Smoker to reach an internal temperature below 150 degrees, open the Smoker and repeat the process of spraying the insides of the smoker. Once this is accomplished you can restart the smoker and begin cooking.

Before you use your smoker always clean the fire grate, empty out the ash pan and firebox. The simplest way to clean the cook chamber is to lightly brush off the interior of the smoke chamber, the diverter and the bottom with a heat tempered brush. Then just take a fireplace shovel and remove all the debris from the bottom of the smokier. Wipe any excess carbon off the bottom and you are ready to go.

* One Note* The flashpoint of animal fat is 350 degrees. Always remember to thoroughly clean your smoker before cooking at higher temperatures.